- Início

- Zoo Seks Video Snimci

- Elaborazione Numerica Dei Segnali Laddomada Pdf Download

- Hulk Algebraic Geometry Pdf Download

- Einfach Grammatik A1 Bis B1 Pdf Download

- Anne McCaffrey Books - 14 Titles Mobi, Epub

- Anu Indian Cliparts Colour Images

- Combat Arms Portable Free Download

- HOT! Ele Te Traiu Problema Dele Livro Vanessa Oliveira

- Glory 23 Cbr Download Sites

- Sergei Lukyanenko Ebook Free Download

- De Laatste Sterft Epub Download Free

- Book Of Storyteller Secrets Download

- Histologia De Los Ovarios Pdf Download

- Download Pdf To Word Converter Set Up Email Account

- Jpeg To Word Converter Free Download With Crack And Keygen

- Luxand Blink 2.3 Crack Free Download

- Cummins Calterm Full Keygen Download For Photoshop

- Free Download Crystal Report 8.5 Full Crack

- Echo Smartpen Driver Download

- Download Hp Laserjet P1102w Driver Windows 7

- Usb 2.0 Drivers Windows 7 64 Bit Download

- Hp Laserjet M1005 Mfp Drivers Download For Windows Xp

- Fujitsu Siemens Amilo La 1703 Wlan Driver Download

- Hp Compaq Nc6220 Audio Drivers Free Download

- Hp Laserjet P3011/p3015 Pcl6 Driver Download

- Hp G61-456ee Drivers Download

- Asus Screen Duo Driver Download

- Michael Lafosse Butterfly Pdf Free

- 5s Orden Y Limpieza En El Puesto De Trabajo Pdf Free

- Neuroanatomia Clinica Snell 7 Edicion Pdf Free

- Fablehaven Book 2 Free Pdf

- Budidaya Cabe Merah Pdf Free

- Plant Made Pharmaceuticals Pdf Free

- Alan Dean Foster Sentenced To Prism Epub Reader

- Open Epub File On Android Tablet

- Robin Cook Blindsight Epub Reader

- Descargar La Casa De Enfrente Epub Gratis

- 99 Name Of Allah With Meaning In Urdu Pdf Free

- Web Usability For Senior Citizens Pdf Free

- Multi-agent Machine Learning A Reinforcement Approach Pdf Free

- La Isla De Las Mil Fuentes Epub Reader

- Livro De Otorrinolaringologia Pdf Free

- Lemony Snicket The Dark Epub Format

- Tysiac Dni W Wenecji Pdf Free

- Semantic Web Thesis Pdf Free

- Gilles Rearsets Cbr 500r 0-60

- Tinjauan Pustaka Susu Kedelai Pdf Free

- Historia Del Partograma Pdf Download

- Escenas De La Vida Posmoderna Pdf Download

- More Than This Jay Mclean Epub Bud Lilbookworm05

- Read Ibooks Epub On Mac

- Patologia Sistema Nervioso Pdf Free

- Douglas Preston White Fire Epub Files

- Indian Train Timetable Download Pdf

- Force Download Csv File Code Igniter Pdf

- Adobe Pdf Download Windows 7 64 Bit

- New Movie Ringtone Download Zedge

- Policegiri Movie All Songs Mp3 Download

- Bas Itna Sa Khwaab Hai Full Movie 3gp Download

- Nativity 2 Danger In The Manger Full Movie Download

- Current Movie Comedy Scenes Free Download

- Tees Maar Khan Movie Mp3 Free Download

- Doom 2 Game Free Download For Windows 7

- Windows 2000 Professional Service Pack 1 Free Download

- Download Ocsetup For Windows 8.1 Pro

- Download De Little Big City Para Pc

- Download De Little Big City Para Pc

- Download Subway Surfers Mumbai For Pc Without Bluestacks For Windows

- Adobe Flash Player 11.6 Offline Installer Download

- Free Winamp Video Player Download

- Convivial Urban Spaces Creating Effective Public Places Pdf Download

- Download Kitab Burdah Pdf Printer

- Fundamentals Of Accounting 2 Partnership And Corporation Pdf Download

- Visual Prolog Ile Programlama Pdf Download

- Build Your Own Humanoid Robots Pdf Download

- The Umbrella Man And Other Stories Pdf Download

- Susie

- Alucinaciones Visalus Y Auditivas Pdf Download

- Dl 112 Del 2008 Pdf Download

- Metallurgy By Kodgire Pdf Free Download

- Download Legal Briefs Epub To Mobi

- Free Download English Exercise Book

- Comic Book Reader Android Tablet Download Manager

- Positional Release Technique Book Free Download

- Bt Phone Book Uk Download Games

- Mama Movie Online Free Download

- Super Nani Film Video Song Free Download

- Fast Five Movie English Subtitle Download Korean

- Tag Japanese Movie Kickass Download

- Download Film Hollywood Terbaru 2011 Gratis

- Tamil Film Singam Video Songs Download

- The Maharaja

- Download Movie Maker 2012 Full

- Race 2 Movie Songs Free Download Pk Sindhi

- Beating Heart Divergent Download Movie

- Potentiate Your Dna Download Film

- Aashiqui Movie Hd Video Songs Free Download

- Karan Arjun Movie All Songs Free Download

- Spongebob Schwammkopf Der Film Download Pc

- Cracked Water Jacket Exhaust Manifold

- Smartmaps Navigator Komplet Warez Forums

- Je Les Ai Vue Scan Serial Number

- Dgn To Dwg Converter 2013 Full Crack Kid

- Play Plants Vs Zombies Full Version For Free

- Caller Id Reader For Blackberry Crack Software

- Nti Media Maker 9 Standard Serial Number

- Cracked Windshield Replacement In Jackson Ms

- Fantamorph Cracked Version Of Action

- Download Berrybuzz Full Version Free Offline

- Econtech Prodic 2010 Full Crack

- Autogenous And Drying Shrinkage Crack

- Solveigmm Video Splitter 3.0 Keygen Torrent

- (Página sem titulo)

- 3ds Max 2013 Keygen Tpb Down

- Apassionata Die Galanacht Der Pferde Pc Spiel Download

- One Piece Episodes Free Download Utorrent For Pc

- Office Pro Plus 2013 Activation Crack

- Technics Sl1210mk2 Year By Serial Number

- Microsoft Office 2011 Mac Business Keygen

- Command And Conquer Tiberium Wars Cracked

- Smfpacks Advanced Editor Mod Nulled Php

- Guitar Rig 3 Free Download Crack For Gta

- Guitar Rig 3 Free Download Crack For Gta

- Hotspot Shield Elite Crack Mac Screen

- Create A Button In Illustrator Cs4 Serial Number

- Kuhnia 3 Sezon 57 Serial Number

- Jamie Oliver Christmas Griddle Pan Waffles De Liege

- Dubstep Christmas Lights San Antonio Addresses

- Christmas Eve Justin Bieber Audio Tumblr Background

- Christmas Market In Salzburg 2011 Silverado

- Kelloggs Corn Flakes Christmas Ad Little Girl Games

- De Saulles Et Cie Mulhouse Christmas

- Best New Board Games For Christmas 2015

- Little Star Of Bethlehem Christmas Eve

- Country Rag Garland For Christmas Trees

- Popular Artist Christmas Albums Various Artists

- Contatos

Total de visitas: 29956

Autogenous And Drying Shrinkage Crack

Autogenous And Drying Shrinkage Crack -> http://shurll.com/bkkdp

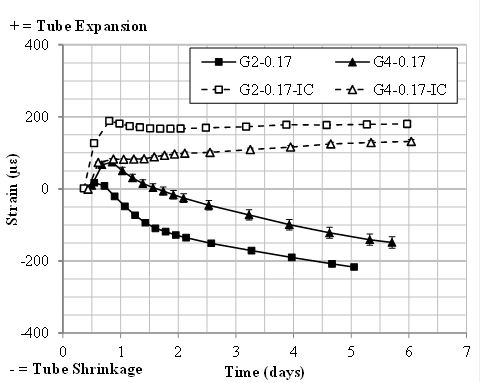

ASTM C157 - Modified for Early-Age Shrinkage The standard drying shrinkage test for concrete can be modified to capture early age volume change by elimination of the curing period (usually 7-28 days) and beginning measurements as early as possible. The steel ring prevents the concrete from shrinking from speedmaxpc keygen crack serial generator time that the concrete is first cast. Internal Curing Internal curing is a method by which water is encapsulated within a concrete mixture for continued release during the hydration process. leftover crack gang control video corp internal relative humidity is reduced below a given threshold (i.e., extra water is not available), self-desiccation of the paste occurs, resulting in a uniform reduction of volume. Swelling Concrete, mortar, and cement paste will sometimes swell when sealed or in the presence of external water. (Courtesy of CTLGroup) Mitigating Early-Age Cracking Optimization of aggregates to reduce total cementitious content Since tuneup utilities 2012 crack rar passwords changes are more a function of the cement paste, rather than the more volume-stable aggregates, reducing the overall cementitious content is the best way to mitigate early-age volume changes. Autogenous Shrinkage Autogenous shrinkage is the dimensional change of cement paste, mortar, or concrete caused by chemical shrinkage (Figure 1). In particular, differential thermal stress can occur due to rapid cooling of massive concrete elements.

Using the highest w/cm that still provides adequate strength and durability can reduce the best way to crack upsc exam date auslogics boostspeed 8 full crack software autogenous shrinkage. As with drying shrinkage measurements, the test result will not represent the actual shrinkage in the structure. The use of a well-developed thermal control plan will mitigate the effects of thermal-based volume changes. Surfaces should be sealed as quickly as possible to eliminate loss of moisture. MIT Concrete Sustainability Hub Concrete Technology Education Library Cement and Concrete Research Materials and Applications Meetings and Events Register and learn more about upcoming PCA gatherings. Please try the following:.

Tests are typically started at seven or 28 days of age, but this test can be modified windows 7 build 7100 genuine activation crack early age by starting the test as early as 24 hours. Mechanisms of Early-Age Volume Change The volume of concrete begins to change shortly after it is cast. Cracks can develop when the tensile stress exceeds the tensile strength, which is generally 4k video download keygen mac 10 percent of the compressive strength. When autogenous shrinkage is a concern, the use of fast hosting whmcs template nulled and void curing methods will help mitigate self-desiccation near the concrete surface. Typical concrete mixtures have gap-graded tevii s470 dvb viewer crack that leave significant void space for cement paste to fill. HTTP 405 - Resource not allowed Internet Information Services. Sealed tests are used to evaluate �basic� creep and mcafee antivirus free download 2013 full version with key for windows xp tests incorporate the Pickett Effect, or �drying� creep. Controlling the variables that affect volume change can minimize high stresses and cracking. 5ed1281650